Sustainability

We are dedicated to the sustainable harvesting of Australia’s hardwood resources. Our belief is that old-growth and rainforest timber should be preserved for future generations. To support this, we focus on sourcing only sustainable regrowth or plantation-grown timber. We advocate for establishing high-value local plantations on suitable farmland while carefully managing our regrowth forests.

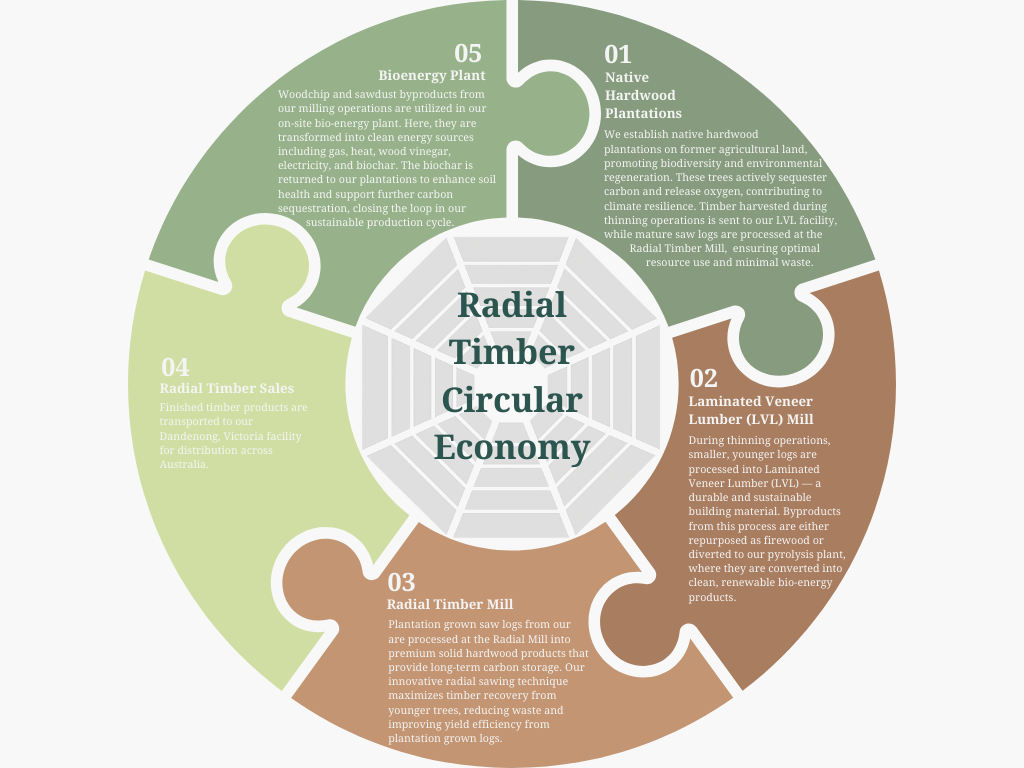

Our goal is to create a circular economy in the way we grow, produce, and distribute timber products. We are investing in innovative techniques to minimize waste, reduce our carbon footprint, and protect forest biodiversity, while still delivering the sustainable timber products we know and love.

We truly believe you can love both timber and trees, if we innovate and work together to do so sustainably.

Click below to learn more about our vision: